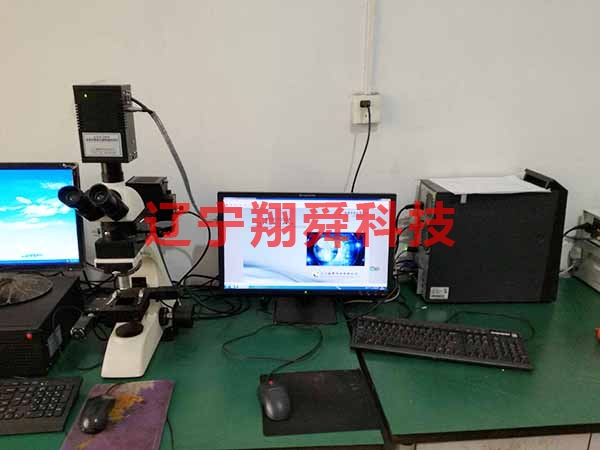

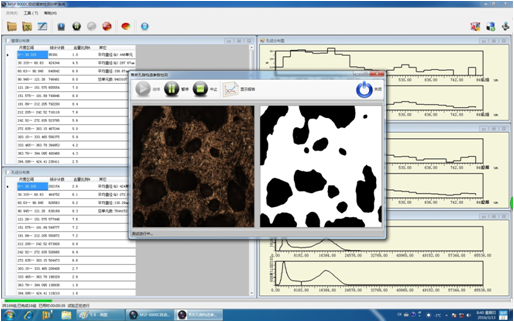

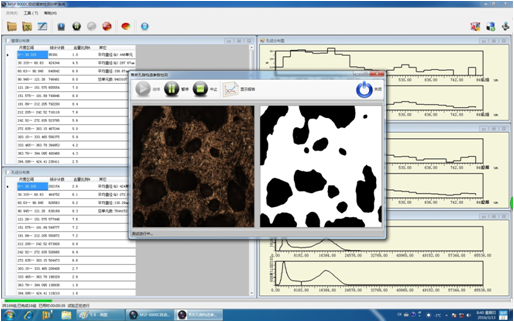

Digital coal and rock analysis POR2000A automatic coke pore distribution detection system (image rapid automatic identification technology)AUTOMATIC COKE PORE DISTRIBUTION DETECTING SYSTEM

(****** rapid microscopic image identification of coke pores)

Application:

It is suitable for quick detection of pore structure of coke, and can obtain such parameters as average porosity (%), average pore diameter (um), average wall thickness (um), pore diameter distribution interval content, and wall thickness distribution interval content.It is used to evaluate the rationality of coking coal blending, to predict the reason of coke's cold and hot strength change and to analyze the mechanism of coke deterioration in blast furnace.Technical features:

1, using image method to quickly and accurately identify the structure of coke hole and wall, fast speed, 1-2 minutes/sample, accurate results!The effective sample quantity can be increased and the representativeness can be improved within the same time.

2. With different magnification multiple objective lens, it can be used for different pore diameter range, and it is also suitable for different pore size distribution detection of other carbon materials;

How to maintain various equipment for coal and rock analysis

One: the size of the test bed.

The size of the test bed should be built according to the style of the test equipment. A reasonable structure can greatly improve the work efficiency and reduce the fatigue degree.If conditions permit, you can buy a professional test bed.

Two: location

In general, our test bed is not allowed to be built in a place where direct sunlight and air convection are available.Because strong light exposure will make the temperature measurement inaccurate, and shorten the service life of electronic components.Air convection will also make the temperature and humidity lost, dust sample even floating.Result in deviation of test results.

Three: the temperature

Domestic latitude and longitude deviation is very large, there are very few areas during the day there is also a great temperature difference, in the absence of indoor constant temperature and humidity equipment, should try to manually adjust the test temperature, so as to avoid adverse effects on the instrument.

Four: basic facilities1.

1.Grounding.Coal quality analysis equipment must be grounded wire, pay attention to the use of safety, lest the instrument leakage or voltage instability causes damage to the instrument or even laboratory staff injured.

2. Power off protection device.The same is for the safety point of view, is one of the test bed necessary facilities.

3. Power supply.Should choose sufficient and high quality power supply.

4, UBS.Some tests are extremely long and complex to prepare.Often a sudden power failure will cause the work can not be completed, there is a good backup power supply to complete the work on time.

5. Test water.The pool should be far enough away from the electronic equipment and not leak.

6. Routine maintenance.Cleaning, drying, good insulation performance is the goal of daily maintenance.Maintaining the test bed as part of your daily work schedule will only make your work more efficient.