Typical coal type automatic and manual comparison test results. doc see the full text please click to download

Typical coal type automatic and manual comparison test results. doc see the full text please click to download

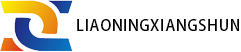

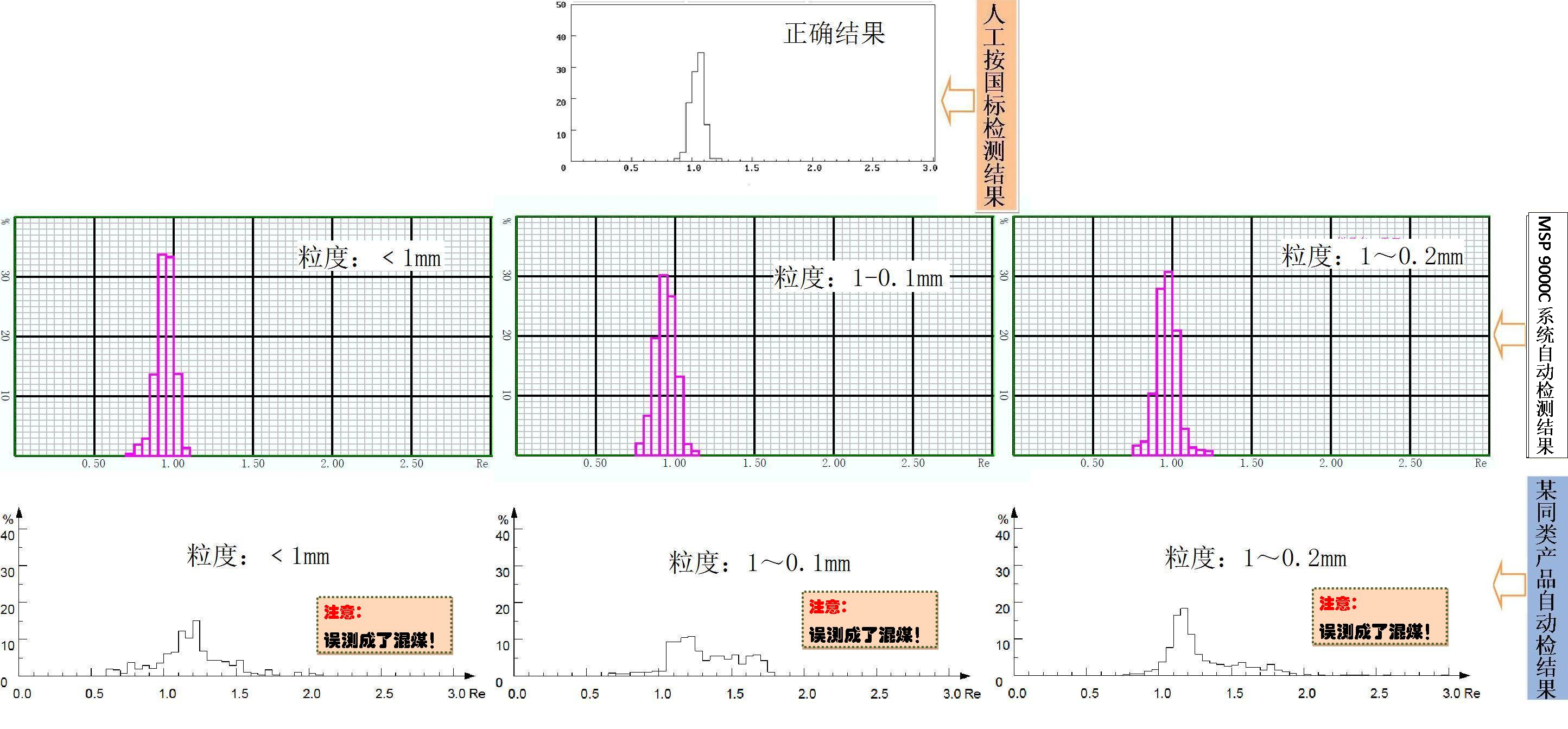

Automatic and manual comparison test results of typical coal types

Coal and rock analysis shows that the difficulty of coal rock automation is:

1. Because the “automatic discrimination identification” of vitrinite and other components is a worldwide technical problem in the field of coal and rock, equipment with poor accuracy will cause single coal to be mis-measured as mixed coal.

2. Due to the complicated factors such as sampling, polishing, and virtual coke, the consistency of the proportions of the distribution map of the coal blend is also a technical difficulty.

The following is a comparison of some typical single coal (vitreous group content 40-60%) and artificial and automatic detection of mixed coal in different crushing granularities and different automatic coal rock equipment:

Figure 1: Random reflectance distribution of low-gray cloud precious coal vitrinite

(Mirror group content: 51.39%)

Figure 2: Random reflectance distribution of the Tianchen coal vitrinite group

(Mirror group content: 59.4%)

The particle size of the sample must be ≤1mm according to the national standard. The 1-0.2mm particle size used in other products of the same kind will seriously affect the proportion of coal blended by “judgment”; (Cause: under the same crushing conditions, the fat coking coal is large, easy to be crushed to below ≤0.2mm, and the resulting distribution map The proportion of the upper coke coal will be less;)

The MSS-2000 system with “identification technology” has a good consistency in the measurement of the national standard ≤1mm granular coal sample, which can be effectively used for coal quality evaluation, and the coal types and possible proportions that are roughly mixed are obtained to guide production;

The same kind of products without “recognition technology” are inferior in accuracy regardless of which particle size coal sample is tested! It is used for the rapid inspection of raw coal in the coking plant and the evaluation of coal quality in the coal mine will mislead production!